Available in North America

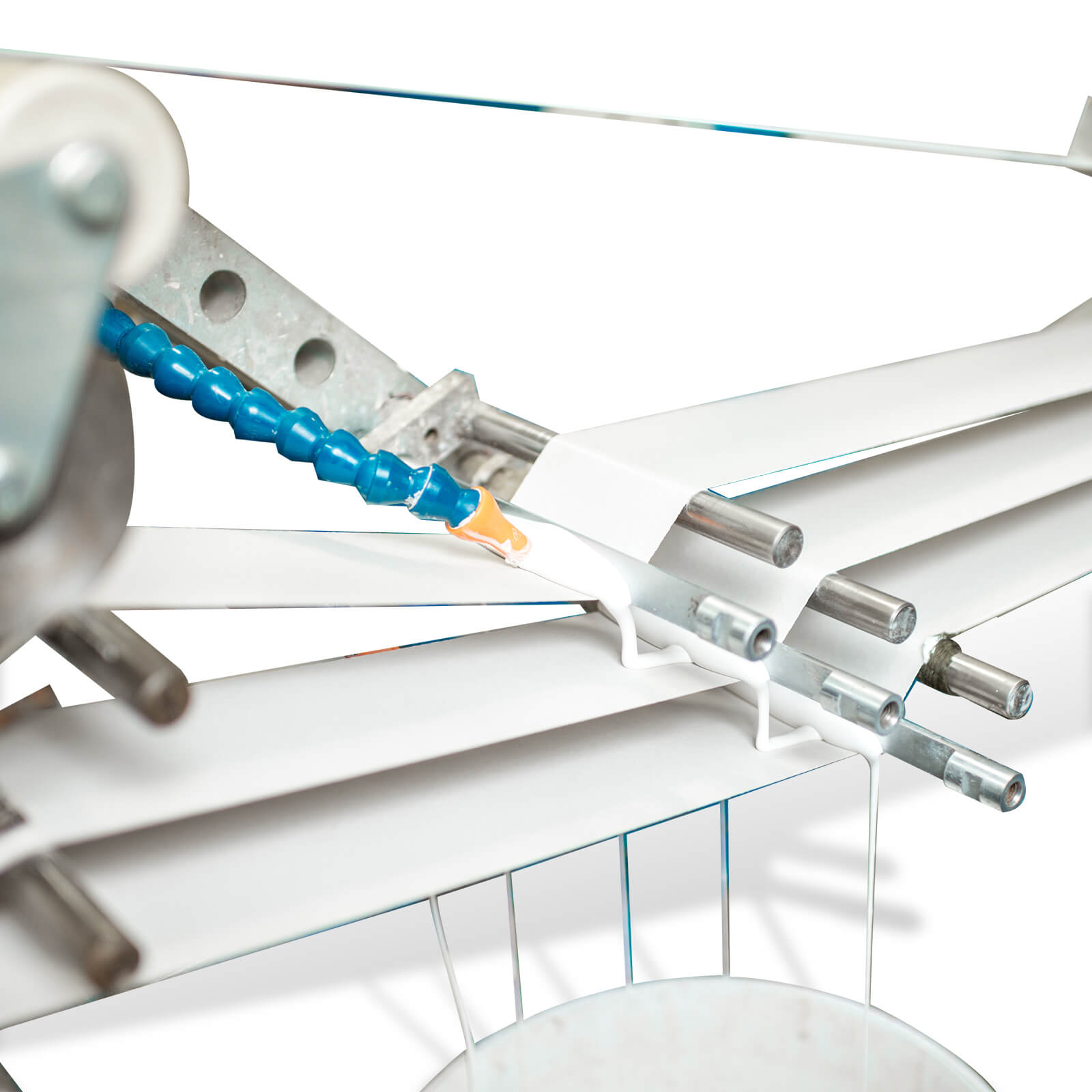

GCore™ Tube Winding Adhesives

Greif GCore(TM) tube winding adhesives are formulated to meet your needs and designed to run on your equipment.

- Rigorous testing

- Computer regulated batching

- Consistent product outcomes

- Multiple adhesive options available

Quality Assurance

Each batch is tested in our quality lab. Greif products meet all established criteria and supporting paperwork is issued prior to shipment

Consistent Products

A computer-controlled batching system assures accurate charging of raw materials and precise cooking cycles. Incoming raw materials are quality inspected, resulting in products with consistent properties and performance.

A Trusted Partner

Greif partners with customers in product development to offer a wide array of water-based adhesives - large and small. Dry blend adhesives are also available.

GCore™ Tube Winding Adhesives Customization and Expertise

Customized formulations.

Wide latitude in formulating allows us to tailor new products to meet and exceed customer requirements for performance and efficiency. Challenging to adhere papers or coatings can be evaluated, and formulations developed to provide a product specific to your unique equipment and paper applications.

Advanced Analytical Expertise

Our lab is equipped with state-of-the-art instrumental analysis tools for product determinations and verifying quality of materials.

Contact Us

Greif has a strict policy against spamming and the company‘s representatives will not reply to unsolicited emails.

The processing of your personal data is done in accordance with the Greif Website Privacy Policy

Data, dimensions, and information provided about products and services on this website are considered nominal values for general-purpose use in evaluating products and services for customers’ specific applications. These are not considered manufacturing specifications.

WE HEREBY DISCLAIM AND EXCLUDE ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Greif Ethics Hotline

To report concerns about possible ethics or compliance violations on a confidential and anonymous basis please visit www.greif.ethicspoint.com or, in North America, you may place a toll-free call to 866-834-1825. Outside North America, where available, follow the directions at www.greif.ethicspoint.com under "Report a Message."