Highlights

- Greif encourages all colleagues to participate in the innovation and transformation of our product portfolio and organizational processes. Through our In-House Entrepreneur program, colleagues are empowered to explore new ideas and bring them to life.

- We aim to select projects based on the following criteria: overall value to Greif and our customers, potential financial return, and the sustainability impact.

- We work collaboratively with suppliers and customers to find innovative solutions to their pain points.

Why Innovation Matters

Product innovation is central to our pursuit of delivering quality products and legendary customer service. Our approach to innovation is aligned with our Build to Last Strategy and its core mission of Protecting Our Future, which encourages the development of new, more sustainable products and services that ultimately help advance a low-carbon and circular economy future. Our innovation approach is also aligned with our mission of Creating Thriving Communities, which enhances colleague safety and safeguards customer health through the continuous advancement of process innovation. Our innovative solutions inspire creativity, cultivate colleague engagement, and promote safety internally while bringing value to customers externally by increasing product efficiency, quality, sustainability, and more.

We understand environmental impacts occur across the value chain of our products. Our approach to innovation aims to support decarbonization and circular solutions through incorporating recycled content, enhancing product recyclability, increasing durability, optimizing resource efficiency, and offering end-of-life solutions.

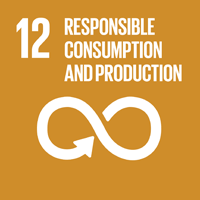

Our Approach

At Greif, we encourage all colleagues and strategic business units to participate in innovating and transforming our product portfolio and organizational processes. We brief our Executive Leadership Team regularly about projects, innovation priorities, industry trends, and other considerations that could impact business operations. Led by the Director of Sustainable Innovation and comprised of representatives from each strategic business unit and corporate function, our Global Innovation Team facilitates idea-sharing and cross-enterprise collaboration.

Our innovation strategy takes a holistic approach, integrating environmental, social, and financial criteria to develop our sustainable packaging solutions. Aligned with the principles of circularity and dematerialization, we work with customers to develop products that meet performance and safety standards while minimizing environmental impacts, thereby increasing customer value. We prioritize creating sustainable products that have a lower carbon footprint, minimize environmental impact, and incorporate more recycled raw materials. We are dedicated to reducing single-use plastic and non-recyclable products by advancing recycled material-based alternatives and eliminating plastic through our innovative barrier coatings.

EnviroRap

Launched in 2024, EnviroRAP is an innovative product developed through our In-House Entrepreneur Program. This sustainable packaging solution is made from repulpable and recyclable material and is designed for use in restaurant take home boxes. Unlike traditional poly-coated packaging, EnviroRAP offers a more sustainable yet cost-effective option. In line with our history of applying circularity principles to our products, EnviroRAP can be returned to our mills and recycled.

Innovation is a driving force behind our product development and circularity efforts. We strive to make products that reduce our impact on the planet while collaborating with internal and external customers to explore creative and innovative solutions to their challenges. In line with this, we are concentrating on implementing product life cycle assessments to advance our circularity strategy and increase transparency around the sustainability of our products. Our focus on product life cycle has encouraged us to think creatively about post-consumer resin products, reconditioning, plastic treatment, and alternative barrier solutions. For more information on our circularity initiatives, please see the Circular Manufacturing section of this report.

ModCan

Launched in 2024, the ModCan is a customer-driven innovation designed to improve waste management through increased safety and efficiency. Designed for laboratory waste and other environmental remediation by-products, the ModCan optimizes space utilization by increasing the number of carboys that fit in drums. Greif engineered this innovative product to emphasize ergonomic safety and versatility while retaining compatibility with traditional drum systems. The ModCan saves up to 42 percent of CO2e emissions compared to traditional labpacks and increases drum utilization from the ‘old way,’ which only uses 36 percent of the drum to the ‘new way’ that optimizes the drum by using 82 percent of the space.We offer opportunities for our colleagues to engage in innovation. Our In-House Entrepreneur Program provides colleagues with opportunities to contribute innovative ideas through a simple portal on Greif’s intranet. Colleagues can submit as many ideas as they want, and if selected, the Innovation Team works to develop the idea through several steps and trials. Our Innovator of the Month recognition program acknowledges and celebrates colleagues who contribute significantly to our innovation initiatives through interviews, pictures, and articles explaining in-house entrepreneurs’ work and innovations.

Colleague Engagement in Innovation

At Greif, we actively encourage our colleagues to engage in innovation and entrepreneurship. We strive to create an inspiring, dynamic, and engaging work environment that promotes creative problem-solving and continuous learning. All colleagues, including those in traditionally operational roles, have the freedom to explore, take risks, and learn from failures. Our Innovator of the Month and In-House Entrepreneurs programs reflect our commitment to engaging colleagues in finding innovative solutions to challenges faced by our customers and industry. When new ideas are presented, Greif applies a lean start up methodology, rapidly developing a minimum viable product and gathering customer feedback before committing additional resources.

Our Innovation Team regularly monitors progress on our innovation objectives, meeting frequently to share updates and align priorities. Innovation plays an important role in protecting the health and safety of our colleagues; the team collaborates with colleagues to develop solutions and implement technologies that make processes safer. In 2024, the reorganization of the company streamlined our approach, enabling us to drive product innovations that are poised to make a global impact.

Goals, Progress, & Performance

Through collaboration with customers and internal stakeholders, Greif aims to improve our products and gain firsthand insights into unmet customer needs to inform future innovation strategies. Our Global Innovation Team is proactively engaging customers by working with Greif’s commercial teams and increasing customer site visits. Innovation is critical to providing legendary customer service. We aim to track the shift in revenue streams that is generated specifically from these innovations. In 2024, $991 million of our revenue was generated from sustainability-tagged products within our legacy Global Industrial Products and our Life Cycle Services businesses.

Laser Markings on IBCs

Greif Sweden/Nordic is the first in the market to replace ink jet markings with laser markings on Intermediate Bulk Containers (IBCs), reducing the use of solvent-based ink during production. By eliminating the use of solvents and ink, the production environment is cleaner. We also are able to reduce the weight of the IBC by one kilogram by removing the plate traditionally used for laser marking. We believe this innovation will set a new standard for markings on IBCs.

Lightweighting and Innovating the Shape of Jerrycans

Greif manufactured our first lighter weight 20 and 25-liter jerrycan models in 2015. This design is 15 percent lighter than the previous model while maintaining performance specifications of the previous design. Due to the reduced weight, the new jerrycans reduce materials and energy used in production by up to 15 percent and have a reduced emissions impact. In 2019, we expanded this product line to include sizes 16 and 18 liters. We now produce our lighter jerrycans in Italy, Israel, Sweden and Singapore.

ECOEX Jerrycans

COEX multilayer plastic packaging combines several layers of different plastics materials into a single structure and offers many barrier performance benefits, particularly for agrochemical and food packaging applications. However, when reground, COEX plastics can only be used in low performance applications. In response to our customers’ need for recyclable packaging with superior barrier performance, we created our ECOEX line of jerrycans. The ECOEX technology enables Greif to produce an innovative, multilayer jerrycan that can be recycled through regrinding processes to produce high performing, UN Certified jerrycans and bottles. ECOEX also reduces costs for our customers who typically pay an increased collection fee for COEX packaging collection after use. We continue to drive innovation that supports our circular economy strategy and meets our customers’ needs. The LATAM GIP team was awarded the 2021 Michael J. Gasser Sustainability Award for their contribution towards our circular economy strategy while meeting the needs of our customers.

A Lighter Approach

In order to respond to customer demands to remove weight and optimize transportation costs, our Greif Latin America colleagues designed a novel plastic drum innovation using a never seen before facetted side-wall approach for large plastic drums. This improvement removed up to 14 percent of the resin in the drum while maintaining performance. Not only does the design reduce raw material usage, it also optimized pallet utilization due to its unique configuration which allows more drums to be transported in the same space as the legacy design. The faceted drum is a more sustainable solution both in reducing natural resource consumption and lowering fossil fuel-based raw material usage and CO2 emissions during transportation.

Better Branding with Drum 360

At Greif, we now have the ability to print high-resolution images directly onto steel drums using the latest print technologies. This capability is the direct result of an investment designed to meet the needs of customers who are looking for ways to differentiate their products and generate impactful packaging design to support the price point of high value products. In addition to adding value for our customers, this process eliminated the need for a standard gas oven, using LED-based UV curing during the production process. This new process saves 0.5 kilograms CO2 per drum. Greif strategically placed the new Drum 360 technology in plants close to customers who use this new technology, in the Belgium, France, Netherlands, Italy, Germany and Poland.

GCUBE Connect: Real-time Tracking for your IBCs

Greif’s GCUBE Connect solution, launched at LogiChem virtual conference, gives real time tracking information about a customer’s IBC through the application of an Internet of Things-based device. A customer-based dashboard displays in real time where an IBC is sited, the level of the filled product and the environmental temperature. This dashboard allows customers to plan in advance for deliveries of filled product and the arrival of new IBCs, as well as schedule collections of empty IBCs. GCUBE Connect also supports better management of residue in the IBCs. Each IBC that enters the facility is automatically weighed to determine how much residue is in the container to determine how it will be treated. This innovation pairs well with Greif France’s ability to pick up and drop off reconditioned IBCs from any site along a customer’s supply chain, as opposed to one single location. Together, they simplify the logistics for the customer and increase transparency.